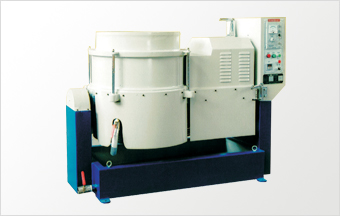

Specifications and technical parameters

1, the work tank section diameter: 200

2, working groove length and height: 17500 x 500

3, total power: about 380V 50HZ 12.8kw three-phase

4. The motor power of the optical motor: 11kw

5, sorting machine motor power: 0.4 x 2

6, feeding conveyor motor power: 0.37kw

7, abrasive return conveyor motor power: 0.75kw

8, equipment appearance size: 3100 x 2200 x 4300

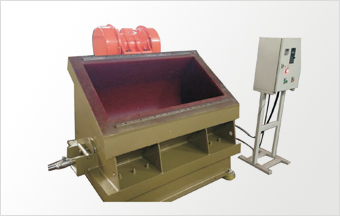

Application and scope

Mainly used to made of metal, nonferrous metal and nonmetal variety of small parts deburring, to oxide skin and removing rust, acute angle inverted Park finishing, especially in some cannot bear greater mechanical stress of thin wall and thin and narrow joint parts and special and complicated molding finishing machining.

The workpiece after the light is not destroyed and the original size accuracy can be changed, and the precision grade 1- grade of the surface roughness of the parts can be improved..

The equipment can be continuous feeding, discharging operation, suitable for continuous production of large quantities.. The workpiece can be put to work. So the interval, the work does not occur between the collision and injured surface. Because the groove lined with polyurethane (PU) rubber, acid and alkali resistance, oil resistance, wear resistance. The wet process is used in the finishing operation, saving labor and reducing production cost..

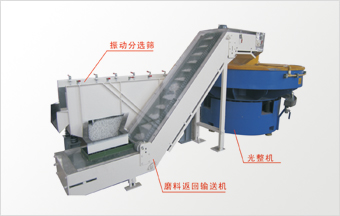

Working structure and working principle

Workpiece by feeding conveyor or by abrasive return conveyor into helical groove, central tank vibration motor vibration high-speed rotation generate strong exciting force, through the action of the spring so as to make the container of vibration, groove cutting grinding block and annular workpieces tumbling motion, extrude each grinding, remove the burr workpiece. To burr parts and grinding block has entered the vibration sorting machine from the outlet of the tank container and sorting machine the workpiece and the grinding blocks are separated. After the separation of the workpiece into turnover into the next working procedure, and grinding block enters the abrasive return conveyor sent to light machine tank container internal circulation work, to continuous material continuous cutting automation finishing.